Okamoto is a leading manufacturer of precision grinding and polishing tools since 1935.

Grinding tools are used in applications of wafer manufacturing, SOI, TSV, MEMS, thin wafers down to 25 um, bonded wafers, bumped wafers, solar ingot grinding, quartz, sapphire, SiC, GaAs, InP and more. Polishing tools used with CMP technology for high throughput and high accuracy. All tools are available up to 300mm. For thin wafer applications, grind/polish systems can be integrated with a mounter, DAF, and detaper equipment as a complete in-line system.

Okamoto is ISO9002 certified.

GNX200BH

Hard material grinder. Model GNX200BH is designed for processing hard materials in full-auto mode. Machine has high-horsepower motor and extra rigid casting to compensate for maintaining tight tolerances.

SPP800ATB

SPP800ATB Polisher is able to preform cassette-to-cassette batch polishing on 4″ to 6″ wafers.

ASM420M

Multi Slicer

Multi slicer, equipped with a high power driving motor of 5.5 kW with a high rigid column for slicing brittle head material.

VG-401H

Semi-Automatic Wafer grinder for hard materials suitable for AlTic, SiC, Glass, Ceramics with in-process wheel dressing. More rigid column and 11 Kw (14.75 hp) high-power motor.

VG-401MKII

Semi-Automatic Wafer Grinder for Hard Materials Suitable for AlTic, SiC, Glass, Ceramics.

VG-101MKII

Vertical Grinder. Semi-automatic wafer grinder with a single grind spindle, with a single chuck table on a shuttle table. Up to 8″ wafers.

VG-202MKII

For SOI wafer / Super precision grinder.

Designed to meet the increasingly tighter

geometric and surface finish requirements.

GDM300

Fully-Automatic Wafer Grinder and Dual Polish In-Line system for wafer thinning in production: 25 um capability. Integrated Edge-grinder optional. Non-contact laser thickness detection optional. Available to dock directly to Detaper/Mounter unit.

ASM200B

Internal Blade Type Slicer.

Fully Automatic large slicer for semi-conductor raw material, capable of cutting ingots up to 200mm diameter.

SPL-120

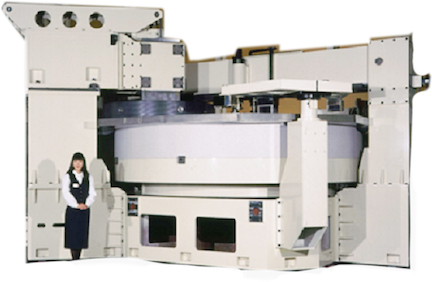

Giant Lapping Machine

Lapping machine with 120-inch plate.

SPL-15

High Accuracy Lapping Machine

Super high accuracy model equipped with air bearing to rotate surface plate.

PNX332B

Final Polisher. Fully-Automatic Polisher for 8″ and 12″ wafers developed for final and reclaim wafer manufacturers, currently maintaining a large world-wide a large market share.

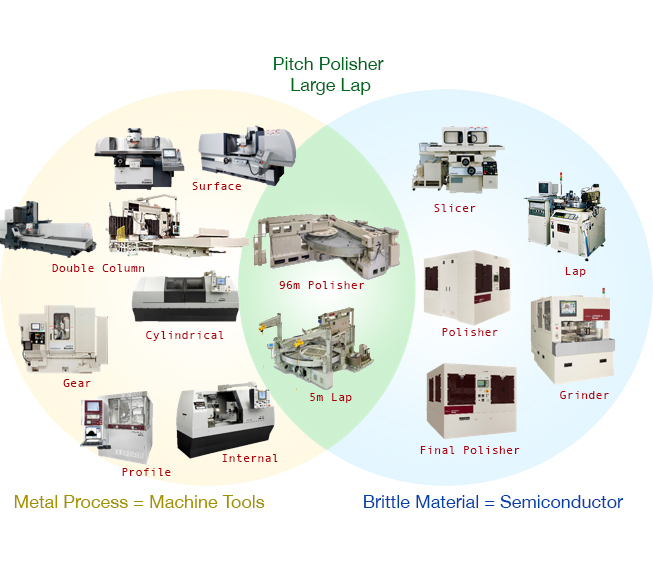

Pitch Polisher

Large plate pitch polisher plate: diameter available to 10 meters

SPP-600S/800S

Semi-Automatic Wafer CMP system.

PL500

GaAs Polisher / 6 Spindle 1 Table

Semi-Automatic

SiG154H

Fully automated multi-step process sequence providing rough and fine grinding.

One clamp centering system ensures proper centering for precision parallel side stock removal grinding. R Chamfering and C Chamfering.

TSV300

The TSV300 has been developed for TSV First application.

Integrated edge grinder, coarse/fine backgrinder, 3-stage polisher, and cleaning. The TSV300 uses our PNX332B polisher technology for via exposure.

GDM300

Fully-Automatic Wafer Grinder and Dual Polish In-Line system for wafer thinning in production: 25 um capability. Integrated Edge-grinder optional. Non-contact laser thickness detection optional. Available to dock directly to Detaper/Mounter unit.

GNX300B

Fully-automatic wafer grinder with down-feed grinding method and Robotics wafer handling. 8″ and 12″ grinder.

GNX200BP

Fully Automatic wafer grinder with down-feed grinding method and Robotics wafer handling.

GNX200B

Model GNX200B grinder is a fully-automatic continuous downfeed grinding machine. Wafers are handled through the machine by a robot, and load/unload arms. Two different stations are used for wafer cleaning after the final grind station.

Okamoto Worldwide

Okamoto Worldwide